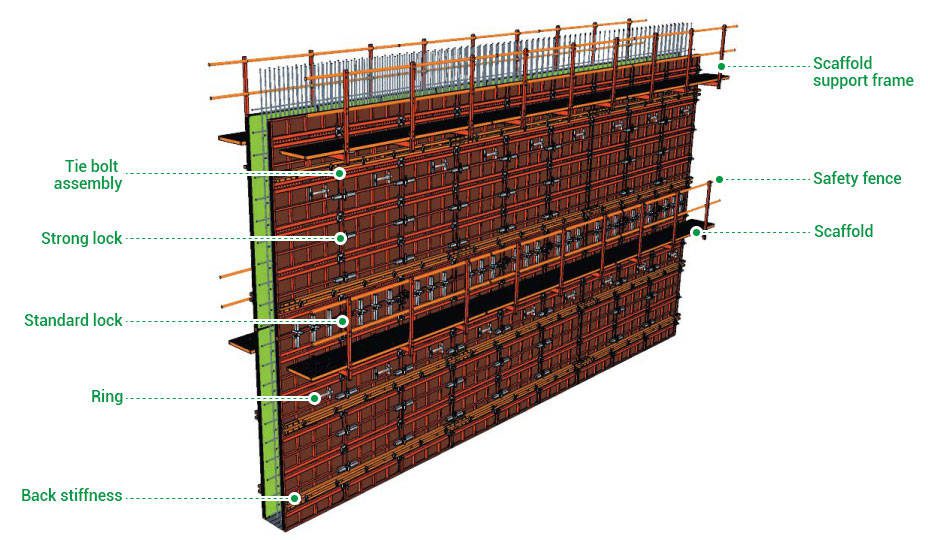

Steel Framed Formwork for Wall is made of a combined structure of steel frame and film – faced plywood. It is a large assembled formwork made up of standard panels, and it offers various assembling forms. This system enables concrete pouring for walls, columns, or slabs. Its assembly and disassembly processes are quick, and it has a relatively light theoretical weight (50kg/m2). Designed to allow workers to assemble the panels promptly with just a hammer and fewer panel clamps, this system requires only a small workforce. With proper care, contractors can expect these forms to be reused more than 30 times before the plywood needs replacement.

Wall Formwork

Cost advantage:

Low material cost, low maintenance cost (simple replacement of plywood is sufficient), and the construction process can be manually transported without the need for mechanical equipment.

Efficiency advantage:

High degree of standardization, flexible assembly, using standard fixtures for quick and simple assembly.

Efficient, Faster,Safer.

- Faster work efficiency

- Modular design

- Durable and low-maintenance panels

- Quick assembly and disassembly

- Suitability for narrow internal spaces

- Seamless connection and efficient hoisting

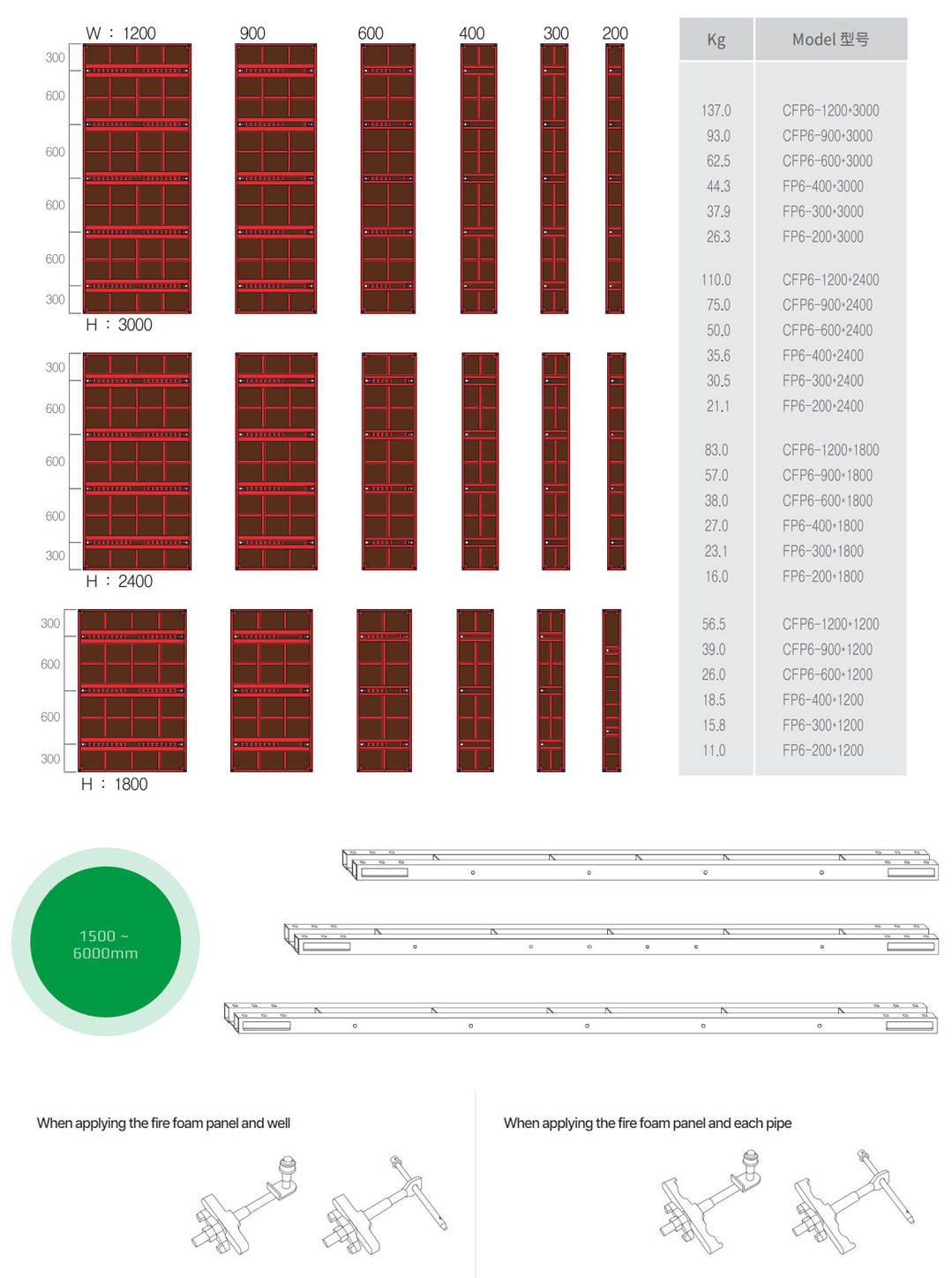

Panel Sizes:

Panel thickness: 64mm

Panel frame: Low carbon steel (surface treatment: baked paint)

Surface: Waterproof plywood surface with plastic layer attached

Various panel sizes

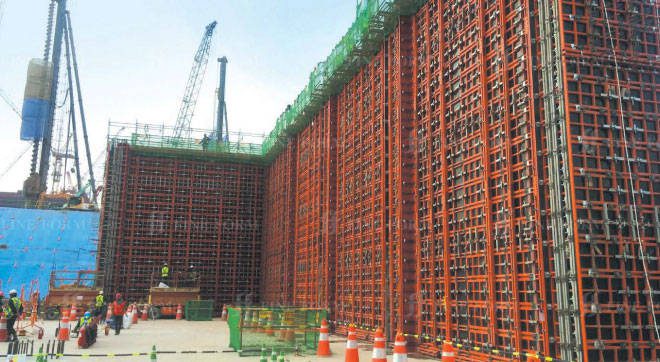

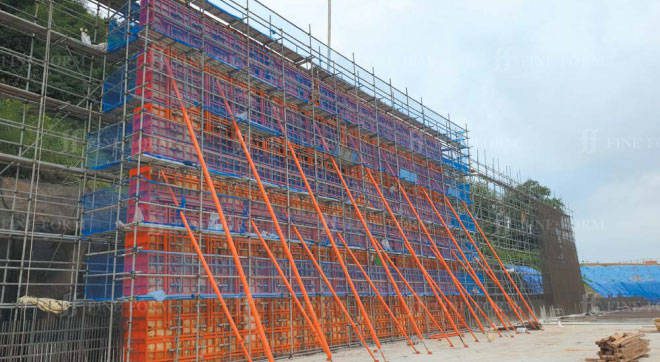

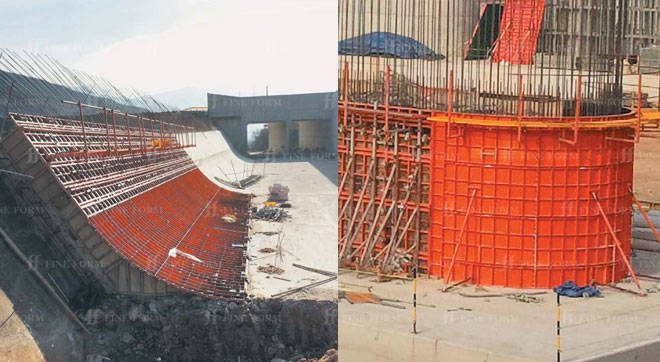

Application cases of Wall Formwork:

On-Site Display:

It can be used for concrete pouring of walls, slabs, columns,beams and bridges, etc. The price we provide is cheap, high quality and low price, welcome to consult.