Smart-64 Lightweight Formwork

SIMPLE INSTALLATION:

Start installing from the internal corner panel according to the formwork arrangement drawing. The panels are connected using standard locking clamps; simple installation can be done with one hammer.

FORMWORK TURNOVER:

1 – Transport the formwork to the upper level via the material hoist, and reinstall the formwork according to the pre-marked positions.

2 – When reinstalling, ensure that the formwork has been cleaned, with particular attention to the panels.

3 – For exterior walls, use a tower crane to lift them as a whole, and accurately fix the Kicker into the predetermined embedded positions.

Efficient, Faster,Safer.

FORMWORK REMOVAL:

nce the concrete strength reaches over 50%, begin dismantling the early removal deck panels. First, individually push the sliding pins of the early removal supports to lower the panels and early removal beams by approximately 200mm, then proceed to remove the panels and early removal beams one by one.

Except for the early removal supports, all other formworks and accessories can be removed, while the early removal supports must be retained for at least three levels. In winter construction, the retention period should be appropriately increased.

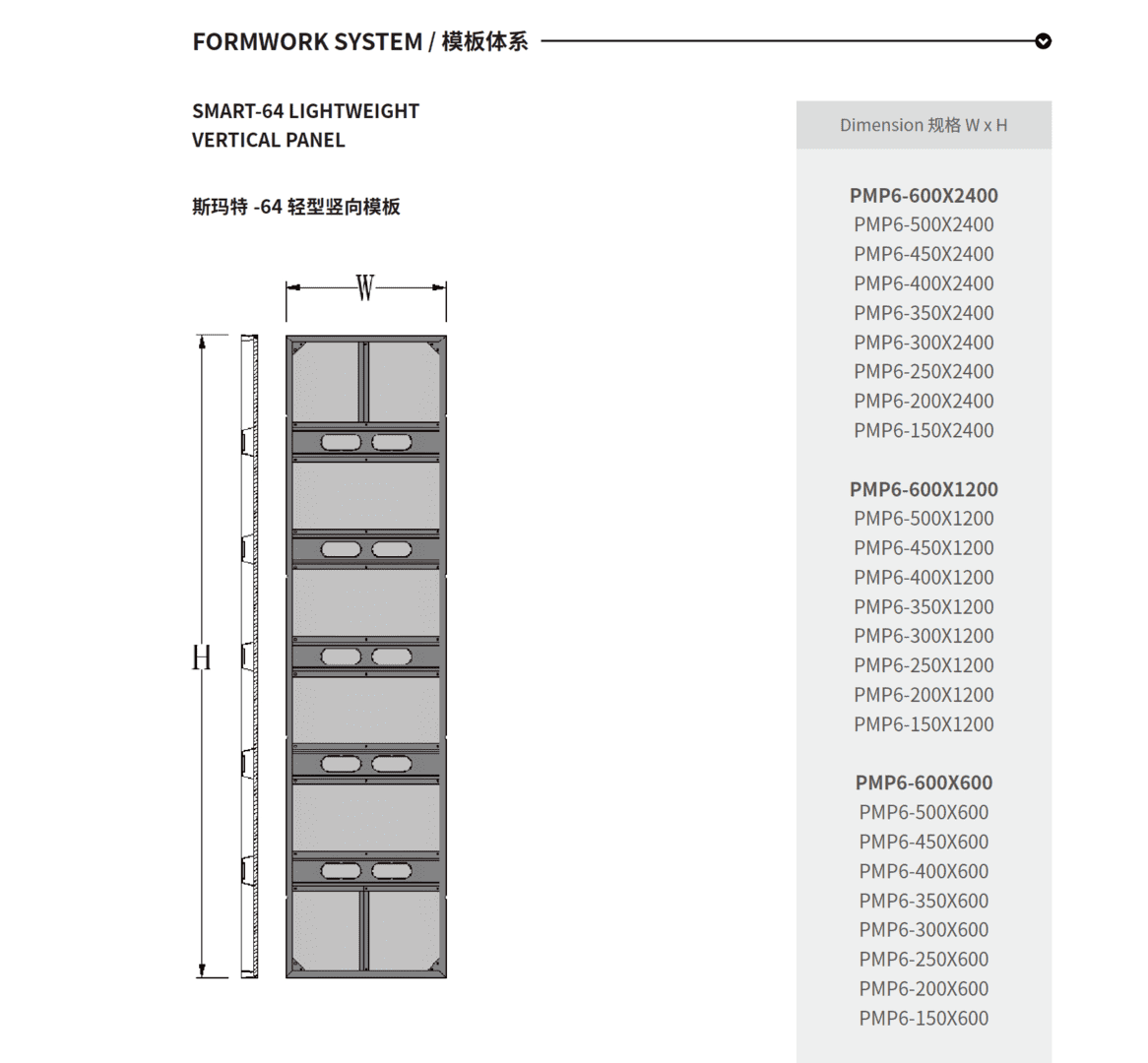

Panel Sizes:

Panel thickness: 64mm

Panel frame: Low carbon steel (surface treatment: baked paint)

Surface: Waterproof plywood surface with plastic layer attached

Various panel sizes

Advantages:good quality, high efficiency, low cost

>> Reduced dependence on labor

Tool-based and modular design, workers install the formwork like “building blocks”.

>> High efficiency

Only two diagonal locks needed to be disassembled and installed during turnover, and each person can disassemble and install 50 square meters per day, which greatly saves labor costs.

>> Adjustable cross-section

Windmill-style connection, only one positive corner lock is needed to adjust the formwork cross-section size every 50mm. One set of formwork meets the needs of different cross-sectional sizes.

>> Good molding quality

Bearing capacity: 50KN/㎡ The concrete surface is clean and tidy, with high flatness and verticality, reducing maintenance costs.

>> Low amortization cost

The steel frame can be used for 5-8 years, and the panel can be replaced. 14mm double-sided coated water-resistant plywood, guaranteed turnover 30 times, greatly reducing the panels amortization cost.

>> High level of civilized construction

No waste, the site is clean and tidy.

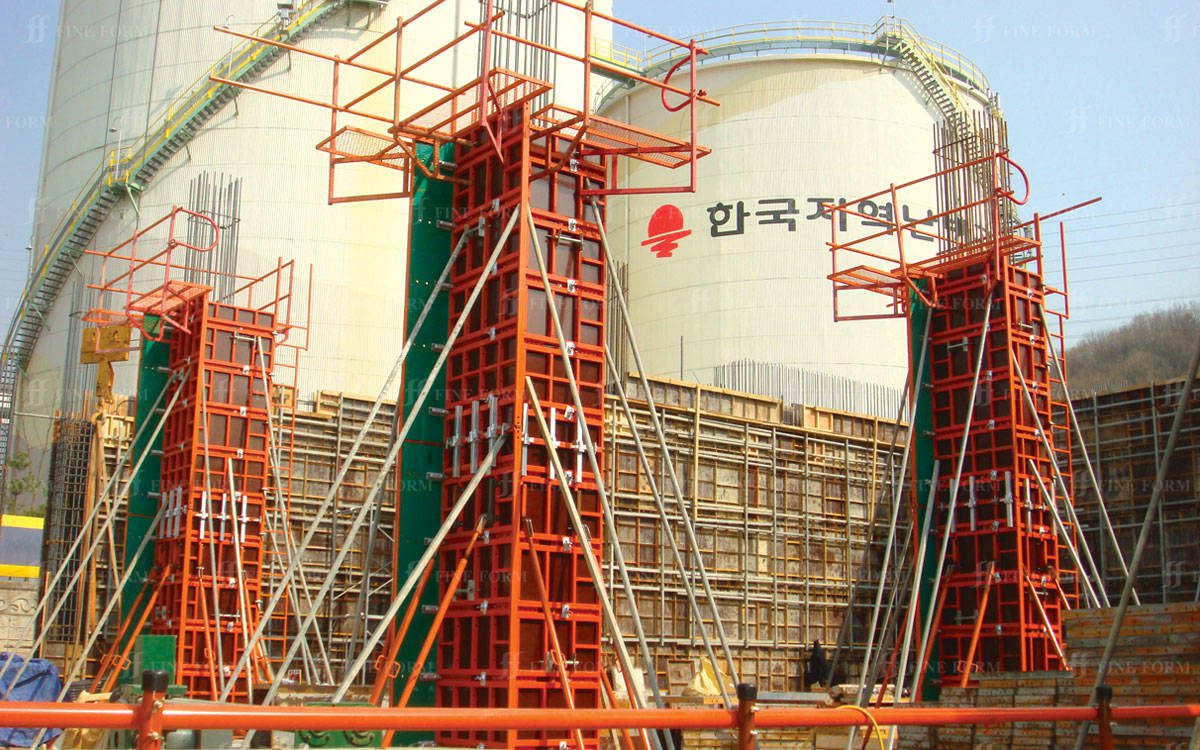

On-Site Display:

It can be used for concrete pouring of walls, slabs, columns,beams and bridges, etc. The price we provide is cheap, high quality and low price, welcome to consult.